Description

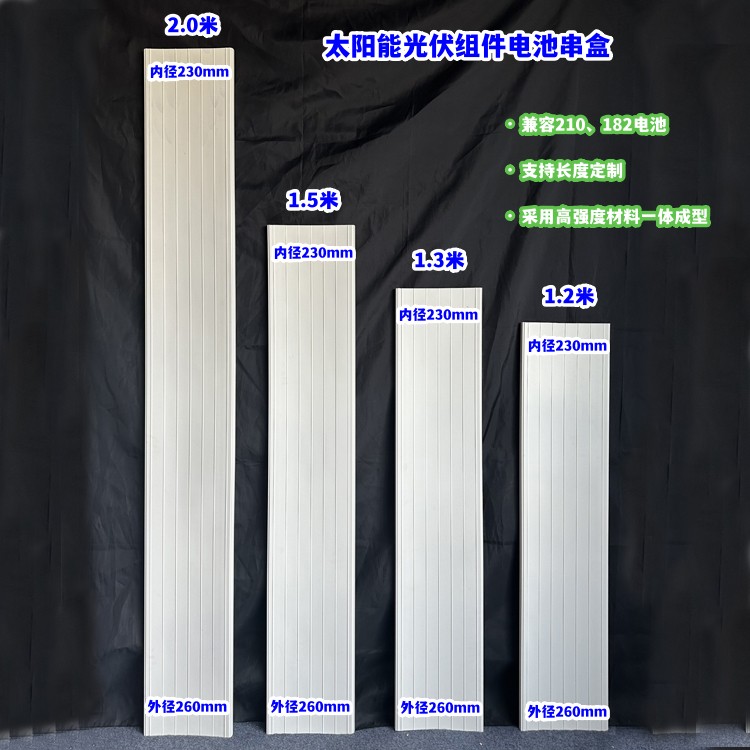

In photovoltaic module production, the Solar Cell String Cassette is a specialized container. It temporarily stores, protects, and transfers series-connected cell strings. Its inner wall is smooth and burr-free. This prevents scratches on the cell strings. The material resists flaking and contamination. It meets the cleanroom requirements of PV workshops.

The core function of Solar cell string cassette

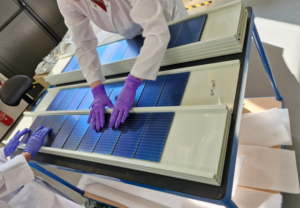

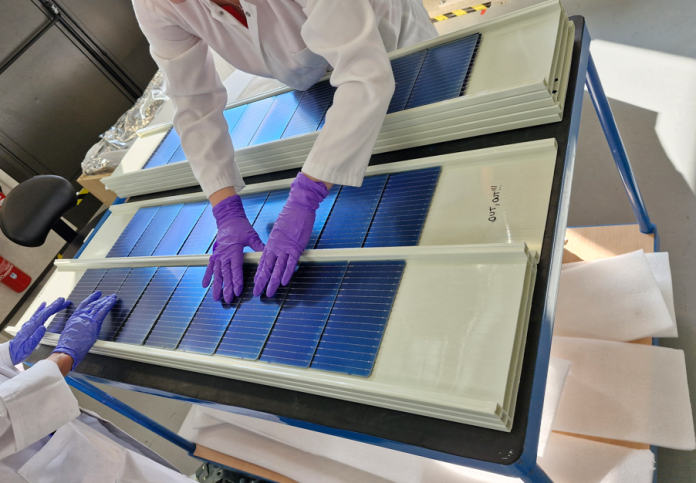

It directly boosts production efficiency. The box serves as a critical automation interface. Automatic stringers place finished cell strings directly into it. A transfer cart then moves the box. A robotic arm precisely picks strings from it for automatic layup. This significantly reduces manual handling and waiting time.

Solar cell string cassette provides physical protection for fragile cell strings. The box shields them from bumps and friction during transfer. It also prevents damage from falling debris. This occurs before the lamination process. The protection ensures string integrity. It fundamentally avoids micro-cracks from manual handling. It prevents breakage and contamination. This directly reduces the scrap rate.

It maintains the alignment of cell strings. The box secures their configuration. This ensures spacing matches design during glass layout. It guarantees correct positioning. This foundation is crucial for subsequent lamination. It ensures final module lamination quality.

The box enables smooth flow. It acts as a standardized carrier. It transports cell strings efficiently on the production line. This transfer is orderly. It enhances overall production efficiency. Solar cell string cassette optimizes the production cycle time.

It effectively controls overall costs. It directly saves expensive cell costs. This is achieved by reducing micro-cracks and breakage. It lessens reliance on skilled handlers. Consequently, rework and scrap from quality issues decrease. The box is sturdy and wear-resistant. It allows for long-term repeated use. Cleaning it is also convenient.

The box enhances production line standardization. It standardizes workshop logistics. This results in a more tidy and orderly floor.It also increases production flexibility. Different string box types hold various cell string specs. This provides a buffer for flexible production. It supports quick changeovers.

Solar cell string box appears simple in design. Its precision engineering addresses core transfer pain points. This occurs in PV module production. It standardizes and automates the process. This tool significantly boosts production efficiency. It ensures consistent product quality. It effectively controls overall costs. Its return on investment is remarkably high.

Product Showcase

Reviews

There are no reviews yet.