Description

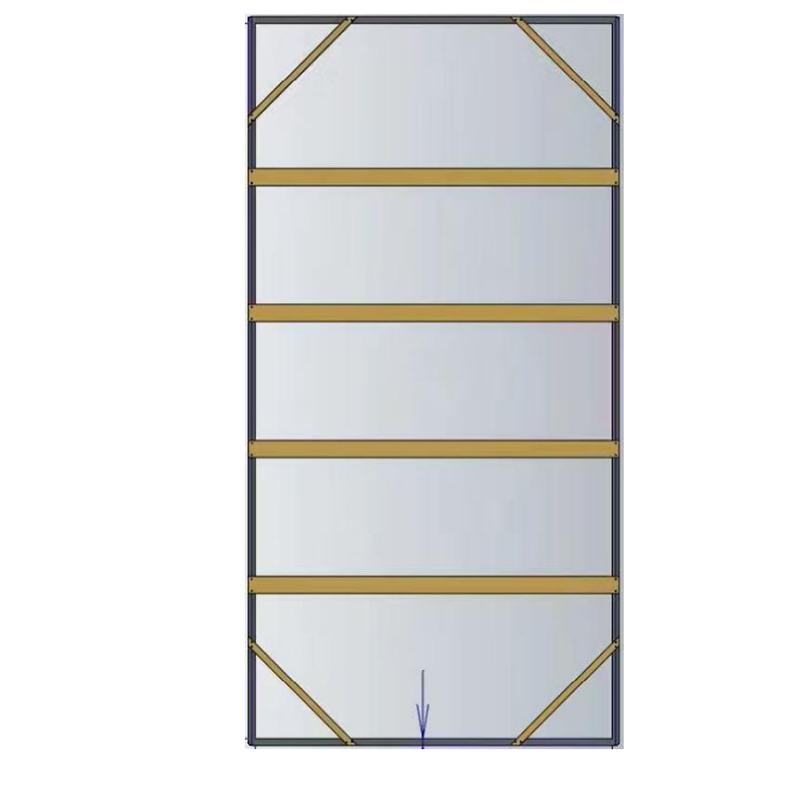

Lamination Frame

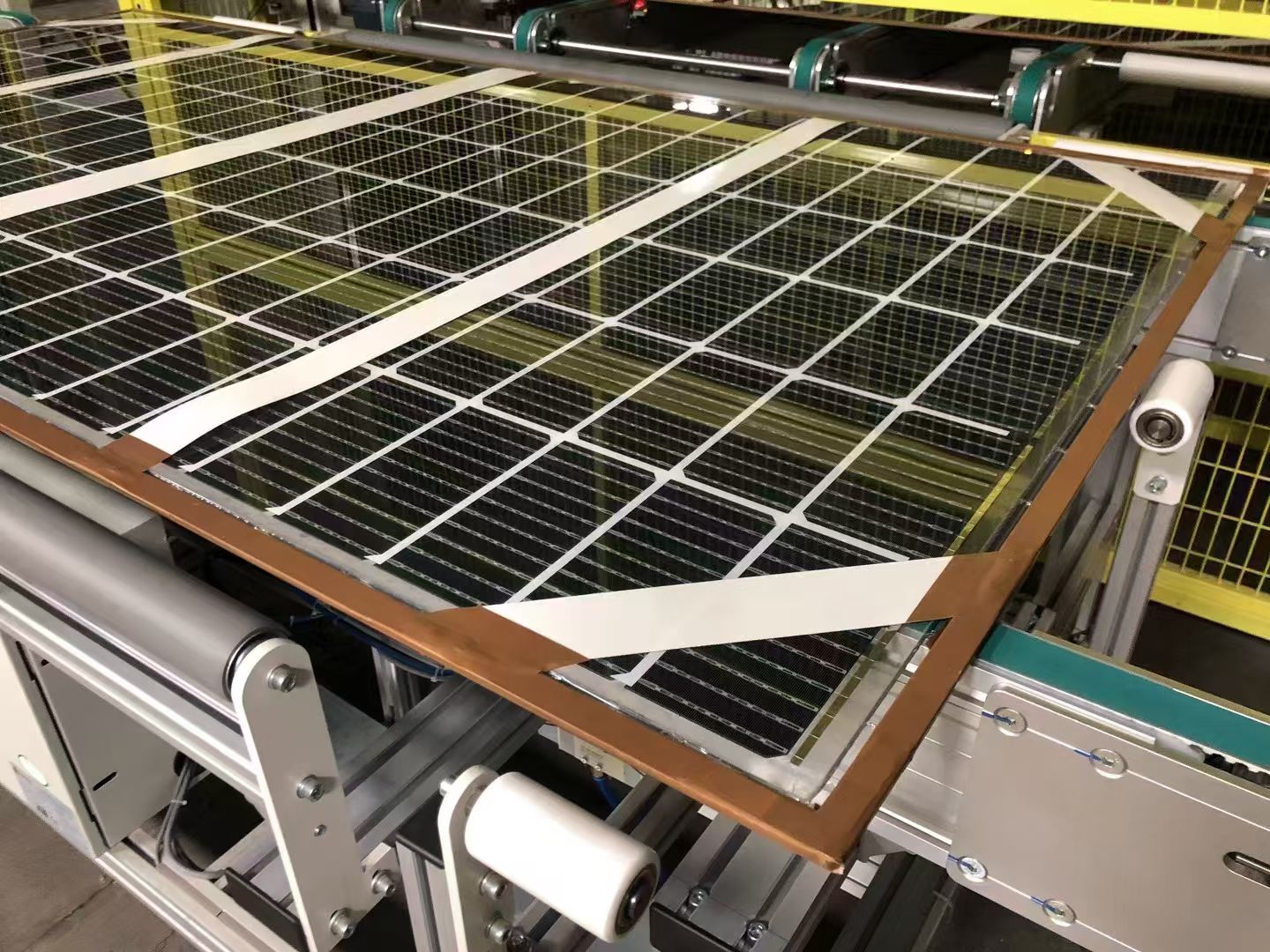

Laminating fixtures Laminated frame can minimize defects (such as bubbles, debris, and misalignment) during the lamination process.

Ensure panel flatness and proper distribution of stress across the entire module.

Improve the yield rate in the manufacturing process of photovoltaic modules.

Reducing the failure rate of photovoltaic modules saves the company costs.

Although the initial cost may be higher, the long lifespan and stable performance reduce the frequency of replacements and downtime, making it more economical in the long run.

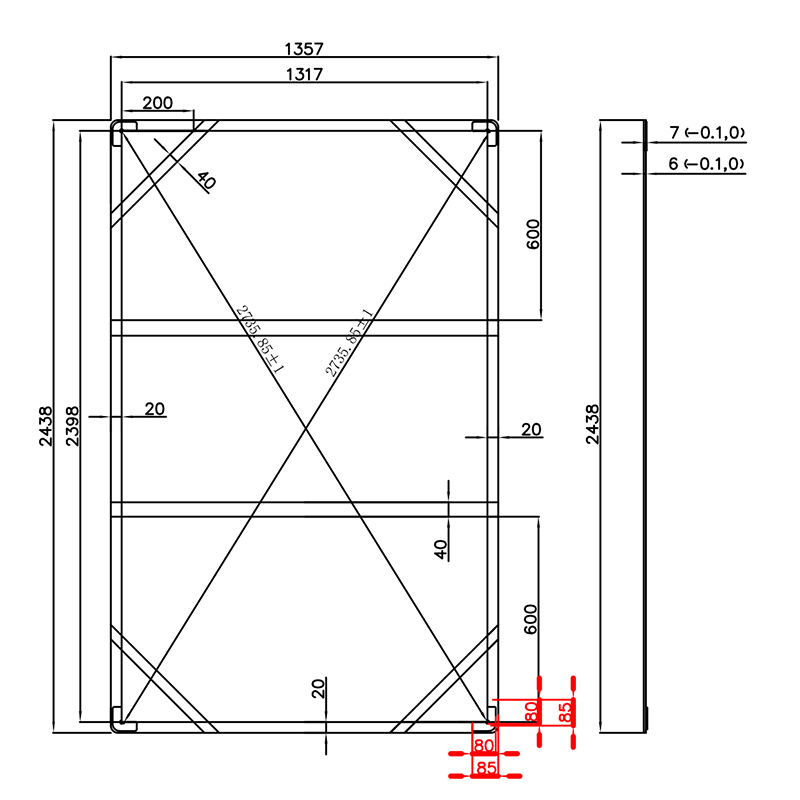

With new technologies like double-glass and shingled modules, not only large-size modules (e.g., 182mm and 210mm) but also diverse structures demand customized lamination tooling based on their specific sizes and process requirements.

It can be hung on Laminate transfer cart in the workshop when not in use.

Laminated Frame Features

Our corner welding process delivers a flawless and extremely strong connection. You can test its sturdiness yourself by striking it with a hammer. This robust construction ensures long-term reliability in demanding environments. We use professional machinery to guarantee highly precise product dimensions. Every frame maintains perfect consistency for your production line.

Laminated Frame Material

We construct the frame from durable and lightweight aluminum alloy. A layer of high-temperature Teflon tape wraps the entire surface. This material combination provides excellent resistance against heat and corrosion.

Package & Transportation

We place each laminated frame in a sturdy wooden crate. These crates fully meet international sea freight requirements. This secure packaging offers superior protection during long-distance transportation. Your products will arrive safely and in perfect condition.

Product Showcase

Reviews

There are no reviews yet.