Description

Function

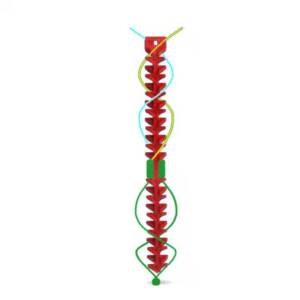

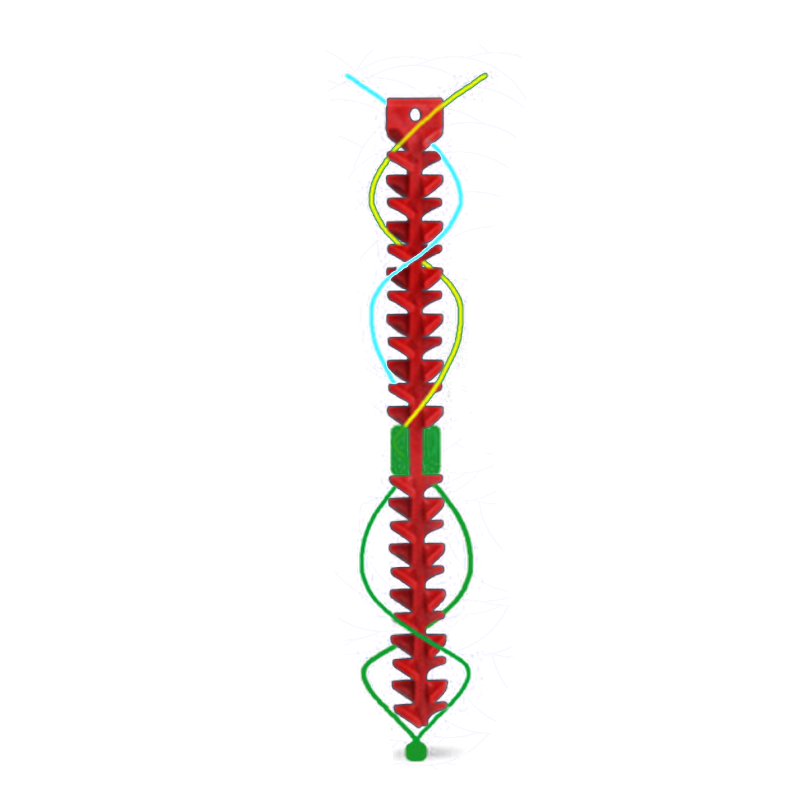

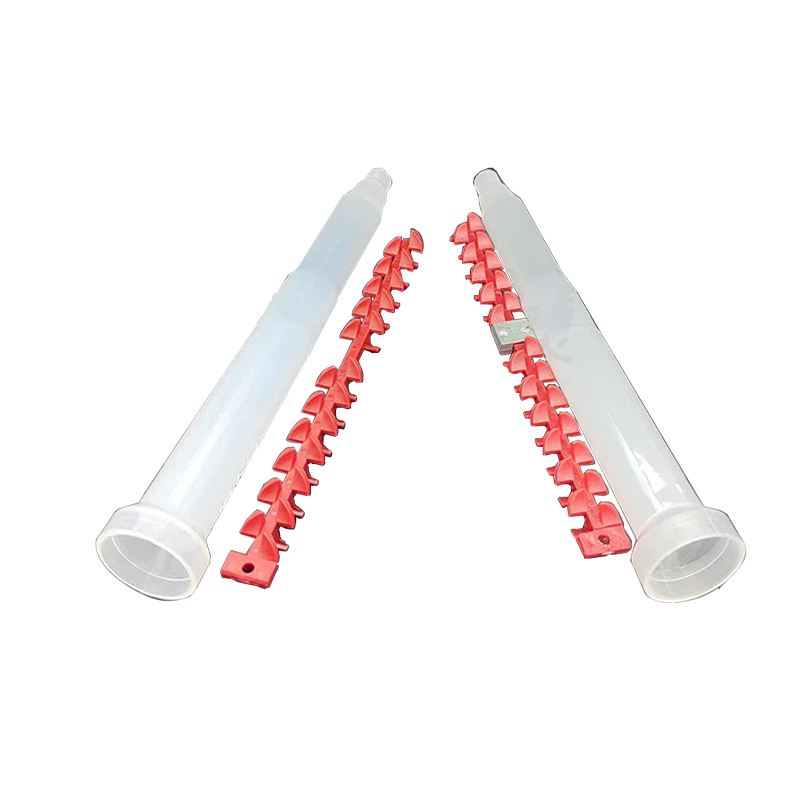

Dynamic mixing tube with metal sensing elements monitors the mixing core’s rotation in real time.It immediately triggers an alarm and shuts down upon detecting stopped rotation.This function prevents batch defects caused by adhesive curing.

How to use a Dynamic mixing tube with metal sensing elements.

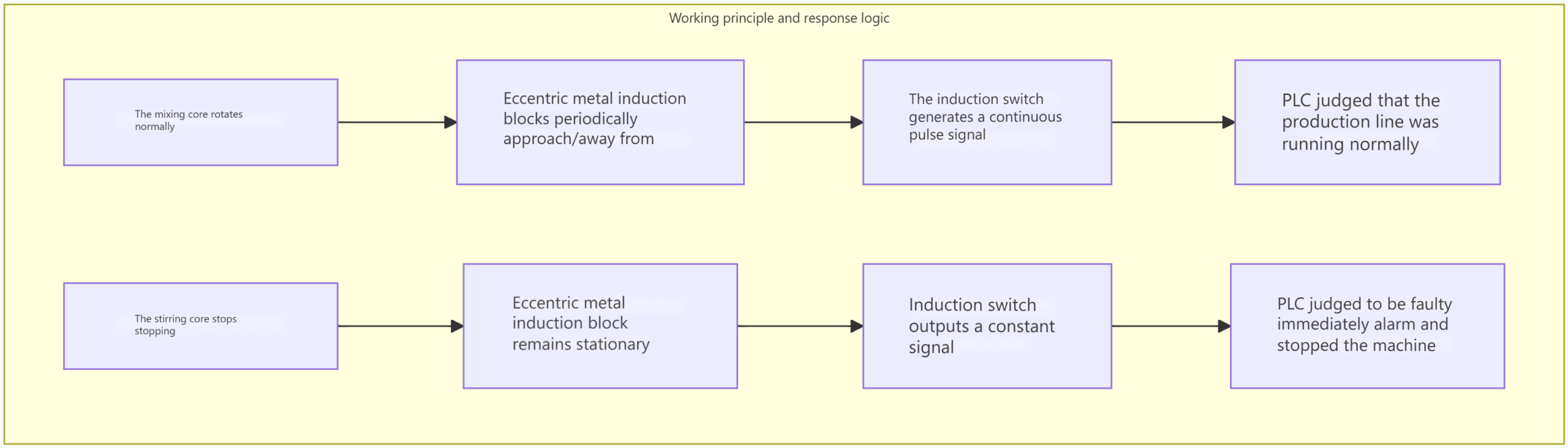

Technicians fix an eccentric metal sensing block onto the mixing core.They mount a proximity sensor externally, aligning it horizontally with the block.. During normal rotation of the mixing core, the eccentric metal block periodically approaches and moves away from the tube wall. Each time it rotates to a position very close to the proximity sensor—typically within a detection distance of 3 mm—the sensor detects it and outputs a signal. In this way, the proximity sensor generates one pulse signal for every complete rotation of the mixing core. The upper-level PLC controller continuously monitors this pulse signal. Continuous pulses indicate that the mixing core is operating normally; once the pulse signal disappears and becomes constant, it signifies that the mixing core has stopped rotating. The system then immediately triggers an alarm and shuts down.

Why is this device being installed?

This device primarily addresses a specific and costly process risk in PV module production:

- Dynamic mixing tube with metal sensing elements prevents batch quality incidents. During the framing of PV modules, a two-component (Part A and Part B) sealant must be dispensed into the junction box. Once mixed, the sealant cures rapidly within minutes. If the motor driving the mixing core fails or if the mixing tube clogs and causes stirring to stop, the sealant will solidify inside the tube. This will prevent effective potting in all subsequent modules, leading to a large batch of defective products and extremely high rework costs.

- Dynamic mixing tube with metal sensing elements protects critical equipment. If the mixing core becomes blocked by cured sealant, it can cause motor stalling, potentially damaging both the drive motor and the mixing tube directly. This device triggers an immediate shutdown to avoid equipment damage.

- Dynamic mixing tube with metal sensing elements meets the demands of automated production. Modern photovoltaic production lines are highly automated. They demand exceptional equipment reliability. This sensing device serves as a “tireless supervisor” by detecting failures instantly. It fulfills unmanned workshop needs by replacing manual inspections.

The difference compared to ordinary sensorsThe difference compared to ordinary sensors

Unlike static sensors commonly used on assembly lines to detect the passage of metal parts:

- Ordinary Static Sensors: They only detect whether a target is present. For example, they check if a part has moved to a designated station

- The Dynamic Monitoring System Here:This system detects continuous motion.It captures periodic pulse signals to confirm rotation.This method enables dynamic process monitoring.

The Value of the Dynamic Mixing Tube with Metal Sensing

In short, this dynamic mixing tube with a metal sensor serves as a critical error-proofing mechanism in photovoltaic module production. Its non-contact design converts mechanical rotation into electrical signals.The control system recognizes these signals.This method achieves the following critical objectives.

It prevents batch defects caused by uneven glue mixing or failed potting.

Preventing damage to core components from stalling safeguards the equipment.

This system enhances automation efficiency with immediate responses to anomalies.It reduces reliance on manual monitoring.It also minimizes production downtime losses.

Product Showcase

Reviews

There are no reviews yet.